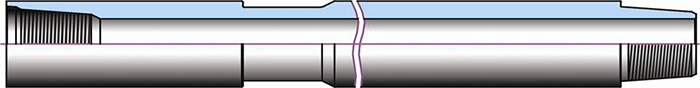

Light-alloy inserted-joint tubing (LAT) are made of aluminum alloys D16T and 1953T1 and designed for operations related to development and exploitation of oil and gas wells as well as for process operations to intensify oil and gas exploitation. Apart from the high specific strength, aluminum alloys are neutral to hydrogen sulphide and carbon dioxide that are often available in the formation fluids making it one more advantage in operation in aggressive medium. LAT became common use in installation of the cement plugs in the well bore with regards to being drilled out easily.

TECHNICAL CHARACTERISTICS OF LIGHT-ALLOY PIPES

|

Nominal geometrical and weight parameters |

LAT 90 х 10,5 (1953Т1) |

|---|---|

|

Pipe length, mm |

9200 |

|

Wall thickness of main pipe body, mm |

10,5 |

|

Pipe diameter, mm

|

90 69 110 |

|

Type of thread |

НКБ-89 |

|

Pipe weight in air, kg |

76,5 |

|

(Limited) Tensile load, kN |

1260 |

|

(Limited) internal excessive pressure, MPa |

98 |

|

(Limited) external collapse pressure, MPa |

95,3 |

Notes

- The above parameters are given for reference.

- The parameters are calculated on the basis of the minimal yield strength of the aluminum alloy for the main section of the pipe body.

- Upon customer request, the pipes can be manufactured with other typical sizes and modified geometrical parameters and threads.